Spring Replacement: When and How to Find the Best Options

ENTER YOUR DIMENSIONS

Select Your Spring Type

COMPRESSION

EXTENSION

TORSION

Select Your Unit of Measurement

Warning Messages

SELECT QUANTITY / CHECK SPECS

PRICING & QUOTES

DOWNLOAD CAD FILES

SPECS & TOLERANCES

FORCE TESTER

RATE | LOAD | TRAVEL

Part Number

AE035-375-19929-MW-1190-MH-N-IN

| QUANTITY | PRICE PER PIECE | AMOUNT |

| loading... | loading... | loading... |

Select the Quantity you want

SPRING DETAILS

Physical Dimensions

Tolerances

ORDER DETAILS

QUANTITY

100 PCS

MANUFACTURING TIME

10 WORKING DAYS

SUBTOTAL

USD $ 00.00

LEFT HAND ADDITIONAL COST

USD $ 00.00

SHIPPING

USD $ 00.00

UPS GROUND

TAXES

0 %

DISCOUNT COUPON CODE

USD $ 00.00

Coupon code removed

Coupon code has expired

PONDA555

Coupon code added

Remove

TOTAL

USD $ 00.00

I AGREE WITH TERMS AND CONDITIONS

I AGREE WITH THE TOLERANCES

Please select to continue

PAYMENT METHOD

Name on Card

Table of Contents

When to Replace Your Springs?

Springs are the hidden heroes in many of our everyday gadgets and big machines. They do their job quietly, keeping everything working smoothly, until one day… they don't. So, how do you know when it's time to swap out an old spring for and replace with a new spring? And where do you find the best spring replacements?

This guide to replace your springs is here to help! We'll show you how to spot the signs that your springs need replacing, share some handy formulas and examples, and even give you some tips to find the right replacement. We'll also highlight some cool tools like the Instant Spring Quote from Acxess Spring that can make finding the perfect spring a breeze. Whether you're a buyer, manufacturer, designer, engineer, or just someone who loves springs, this article has got you covered.

How to Recognize the Signs of Spring Wear and Tear?

Understanding the signs of spring wear and tear is crucial for maintaining optimal performance and avoiding unexpected breakdowns. Here's a detailed look at how to recognize when your springs need replacing.

Reduced Elasticity

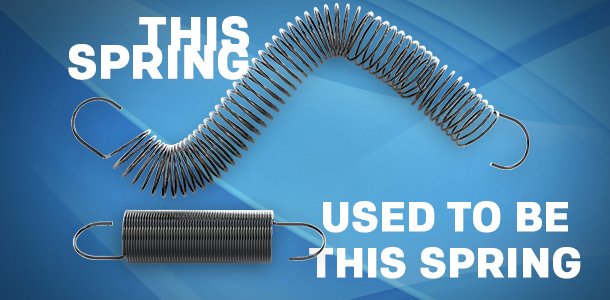

A primary function of a spring is its ability to return to its original length, shape, or free leg position after being compressed, stretched or twisted. Over time, springs can lose this essential property, known as elasticity. Reduced elasticity may be caused by inferior spring design, prolonged use, excessive load or too much travel deflection. To check for reduced elasticity on compression springs first consult the original spring dimensions like free length on the original compression spring then measure the compression spring free length that's been in use to compare the free length to the original spring. If the free length of the compression springs that's been in use is shorter than the original compression spring free length, then you have “reduced elasticity”. This means that in losing free length you have lost travel which means you will not get the same amount of load or force from the spring. ¿Why? Because force equals k * x which is travel (displacement) F=kx . Your compression spring free length is now shorter and has taken a set in free length, meaning the spring can NO longer travel or deflect all the distance it used to and therefore the spring cannot obtain all the necessary load force it once used too. It's time for a new replacement with a new spring design.

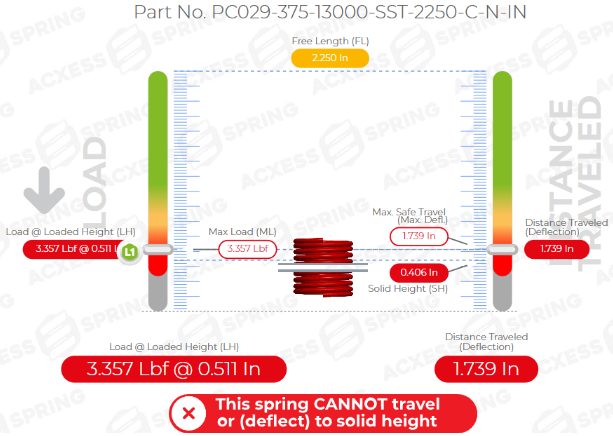

Example: Let say you have a compression spring with a free length of 2.25 inches and a spring rate of 1.93055 lbs/in, and you need to apply a force of 3.4 lbf for a travel distance of 1.8 inches, close to its solid height, if the spring is unable to travel this distance, then a replacement spring is necessary. To determine if the compression spring can handle the specified force and travel distance, we need to calculate the actual deflection using F=kx and compare it to the desired travel distance.

Using the formula F=kx

x = k ÷ F

Substitute the given values:

x = 3.4 lbf ÷ 1.93055 lbs

Calculate the deflection:

x = 3.4÷ 1.93055

x ≈ 1.76inches

The actual deflection calculated (1.76 inches) is slightly less than the desired travel distance (1.8 inches), meaning that the spring needs a replacement. Let’s test it using the Online Spring Force Tester

Visible Deformation

Physical inspection of springs can reveal visible signs of wear and tear. Look for any bends, kinks, or irregular shapes. Deformation often indicates that the spring has been subjected to forces beyond its design limits, leading to permanent changes in shape and it's time for a replacement spring. Regular visual inspections can help catch these issues early.

In automotive suspension systems, a deformed spring can affect ride quality and handling. If you notice your vehicle sitting lower than usual or experiencing uneven tire wear, it might be due to a deformed suspension spring. Then it's time for a replacement spring.

Corrosion

Springs exposed to moisture or corrosive environments can suffer from rust and other forms of corrosion. Corrosion weakens the metal, reducing the spring's ability to perform its function. Regularly inspect springs for signs of rust, pitting, or discoloration, especially if they operate in harsh environments.

Industrial springs used in outdoor applications, like agricultural machinery, are prone to corrosion. Regularly checking these springs for rust can prevent unexpected failures during critical operations.

Fractures or Cracks

Small fractures or cracks can develop in springs due to fatigue or sudden impacts. These minor defects can quickly escalate into complete spring failure. Using a magnifying glass during inspections can help identify these small but critical signs of wear.

In precision instruments, such as medical devices, even small cracks in springs can lead to malfunction. Regular detailed inspections are crucial to maintaining the reliability of these devices.

Unusual Noises

Squeaking, grinding, or other unusual noises often indicate internal wear within the spring or its surrounding components. These sounds can result from friction between damaged spring coils or from the spring rubbing against other parts due to misalignment.

In mechanical clocks, unusual ticking or grinding noises might indicate that the internal springs are wearing out and need replacement to maintain accurate timekeeping.

Key Calculations and Formulas for Spring Evaluation

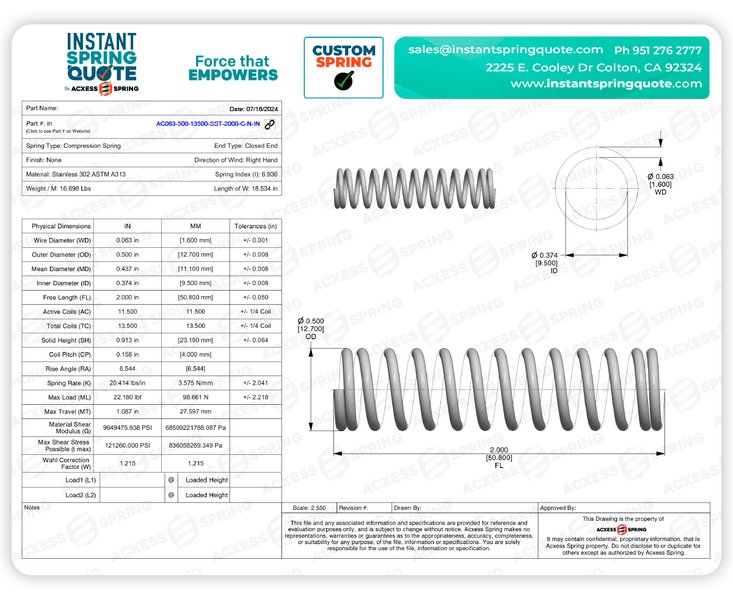

Evaluating a spring’s condition is crucial for ensuring optimal performance and preventing mechanical failures. This section will cover essential calculations and formulas for assessing a stainless steel compression spring with the following specifications:

| Part Number: | AC063-500-13500-SST-2000-C-N-IN |

| Wire Diameter (WD): | 0.063 inches |

| Outer Diameter (OD): | 0.5 inches |

| Free Length (FL): | 2 inches |

| Total Coils (TC): | 13.5 |

| Spring Rate (k): | 20.414 lbs/in |

Hooke's Law

Hooke's Law describes the relationship between the force exerted by a spring and its displacement or distance traveled:

F = k ⋅ x

Where:

-

F is the force exerted by the spring (in pounds).

-

k is the spring constant (in pounds per inch).

-

x is the displacement from the spring’s equilibrium position (in inches).

Example Calculation: If the spring is compressed by 1 inch, the force exerted by the spring is:

F = 20.414 lbs/in × 1 in =20.414 lbs

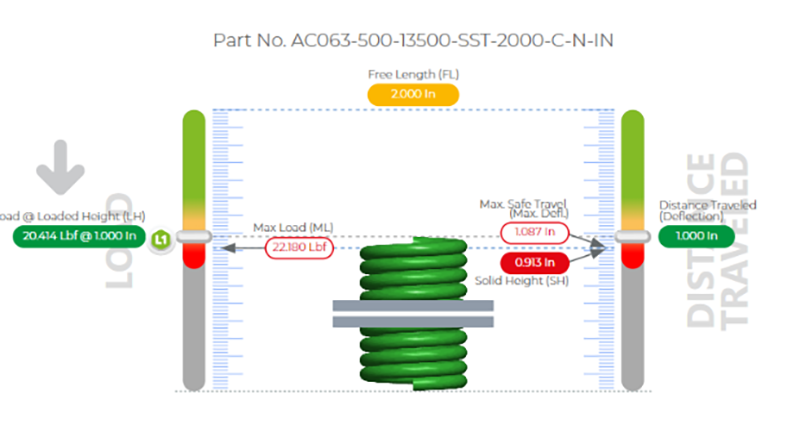

Maximum Load and Travel

To ensure the spring can handle the required load without permanent deformation, you should verify the maximum load and travel capabilities. If you compress the spring by its maximum travel distance, the force exerted by the spring is:

F = 20.414 lbs/in × 1.087 in = 22.180 lbs

This confirms that the spring can handle the maximum load of 22.180 lbs without exceeding its travel limit of 1.087 in.

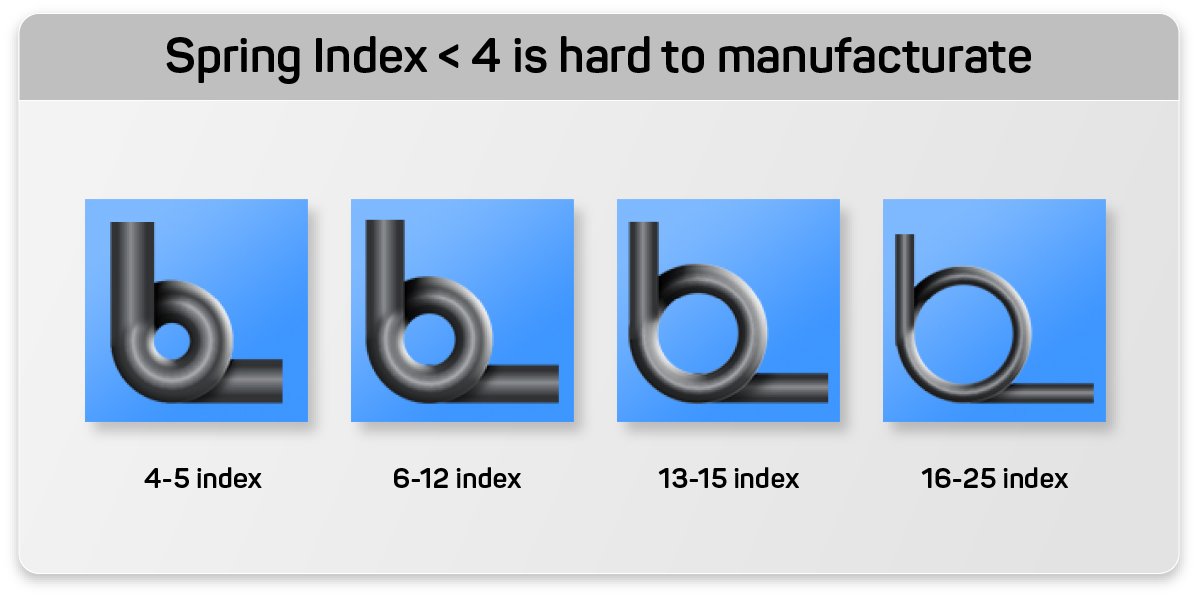

Spring Index and Stress

The spring index (I) is a measure of coil tightness and is calculated as:

I = MD ÷ WD

Where:

-

MD is the mean diameter of the spring (outer diameter minus wire diameter).

-

WD is the wire diameter.

For our spring:

MD = 0.5 in − 0.063 in=0.437 in

I = 0.437 in ÷ 0.063 in ≈ 6.94

A spring index between 6 and 12 is considered optimal for most applications, indicating that this spring is within the suitable range.

Shear Stress

Shear stress (t max) in the spring can be calculated using the formula:

t max = 8 x F x MD ÷ π x WD^3

Where:

-

t max is the shear stress (in psi).

-

F is the force exerted on the spring (in pounds).

-

MD is the mean diameter of the spring (in inches).

-

WD is the wire diameter (in inches).

For the maximum load of 22.180 lbs:

t max = 8 x 22.180 lbs x 0.437 in ÷ π x (0.063 in)^3 ≈ 121,260 psi

This shear stress matches the maximum shear stress capacity of the spring, indicating it is operating at its limit.

What to consider when replacing a Spring?

When it comes to replacing springs, several critical factors need to be considered to ensure you find the best replacement for your specific application. Here are some guidelines to help you navigate this process.

Material Quality

The quality of the material used in a spring is paramount. High-quality materials ensure longevity, reliability, and consistent performance. Here are three common materials for springs, each with unique properties suitable for different environments and applications:

-

Music Wire: This high-carbon steel alloy is known for its high tensile strength and excellent fatigue resistance. It is often used in high-stress applications where repeated loading and unloading occur, such as in automotive springs and piano wires.

-

Stainless Steel: Offers excellent corrosion resistance, making it ideal for applications exposed to moisture or harsh chemicals. It is commonly used in medical devices, food processing equipment, and marine applications.

-

Chrome Silicone: This material provides superior strength and heat resistance, making it suitable for high-stress and high-temperature environments. It is frequently used in industrial machinery.

Maximum Safe Load and Maximum Safe Travel or Deflection

Make sure the springs load and travel distances that you input onto your spring are within the maximum safe load and maximum safe travel of the springs design. This is the most important feature of a great spring design that the user does NOT go past the maximum safe load or maximum safe travel that the spring design is for. The user's spring needs to stay within the maximum allowable load and the maximum allowable travel or deflection for the spring to keep its elasticity so the spring will not “take a set”. For if the user exceeds the maximum safe load or maximum safe travel the spring will take a set in free length and could deform or possibly break.

Manufacturer Reputation

Choosing a reputable manufacturer is crucial. Look for manufacturers known for their quality control, customer service, and adherence to industry standards. A reliable manufacturer will provide detailed specifications, material certifications, and testing reports.

-

Acxess Spring: Known for their high-quality replacement springs and innovative tools like the Instant Spring Quote, which helps streamline the process of selecting and ordering custom springs.

Customization Options

Depending on your needs, you might require custom springs with specific dimensions, materials, or performance characteristics. Ensure the manufacturer offers customization options and can meet your exact requirements.

-

Instant Spring Quote: This tool from Acxess Spring allows you to input specific parameters and receive an immediate quote for custom springs, ensuring you get exactly what you need without lengthy back-and-forth communications.

Utilizing Advanced Tools for Spring Selection

Modern tools and technologies can significantly simplify the process of selecting and testing new springs. These tools provide accurate simulations and visualizations, helping you make informed decisions.

3D CAD Models

3D CAD models allow you to visualize the spring within your design, ensuring it fits perfectly within the assembly. These models help in checking spatial constraints and interfacing with other components.

-

Acxess Spring: Offers a comprehensive library of 3D CAD models that you can download and integrate into your design software. This ensures the spring will fit and function as intended in your application.

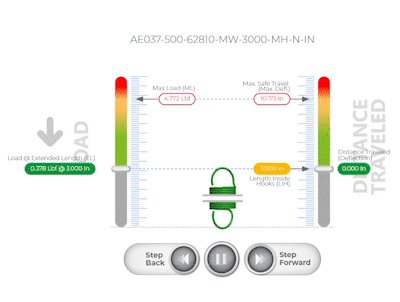

Online Spring Force Tester

The Online Spring Force Tester enables you to simulate the forces on your spring under different loads. By inputting parameters such as wire diameter, outer diameter, free length and material type, you can predict how the spring will perform in real-life applications.

-

Acxess Spring: Their Online Spring Force Tester is invaluable for engineers and designers who need to ensure their springs meet specific performance criteria. This tool helps validate your design before physical prototypes are made, saving time and resources.

How to Find the Right Replacement Spring?

Step 1: Identify Your Requirements

Before you start searching for a replacement spring, clearly define the specifications and performance requirements. These include:

-

Dimensions: Measure the wire diameter, outer diameter, free length, and total coils of the existing spring.

-

Material: Determine the material required based on the application environment. Common materials include Music Wire for high tensile strength, Stainless Steel for corrosion resistance, and Chrome Silicone for high-stress and high-temperature environments.

-

Load Capacity: Calculate the load capacity the spring needs to handle. This includes the maximum force it must withstand and the required spring rate.

-

Environmental Conditions: Consider factors such as exposure to moisture, chemicals, or extreme temperatures which will influence the choice of material.

Step 2: Use Advanced Tools

Utilize modern tools and technologies to streamline the process of finding the right spring.

-

Instant Spring Quote: This tool from Acxess Spring allows you to input your specifications and get an immediate quote for custom springs. By entering parameters such as spring type, dimensions, material, and quantity, you receive a detailed quote almost instantly. This saves time and ensures you get a spring that meets your exact needs.

Example: An engineer working on a prototype may use the Instant Spring Quote to quickly obtain a price and delivery time for a custom stainless steel spring, ensuring the prototype development stays on schedule.

Step 3: Check Manufacturer Credentials

Choosing a reputable manufacturer is essential to ensure you receive high-quality springs. When evaluating manufacturers, consider:

-

Certifications: Look for manufacturers with relevant industry certifications, such as ISO 9001, which indicate a commitment to quality.

-

Customer Reviews: Read reviews and testimonials from other customers to gauge the manufacturer’s reliability and customer service.

-

Industry Experience: Prefer manufacturers with extensive experience in the spring industry, as they are more likely to provide high-quality products and knowledgeable support.

Recommendation: Acxess Spring is a top choice, known for their high-quality products, industry expertise, and excellent customer service.

Step 4: Conduct Performance Testing

Performance testing is crucial to ensure the spring will function as expected in your specific application. Utilize tools and methods such as:

-

Online Spring Force Tester: This tool from Acxess Spring allows you to simulate the forces on your spring under different conditions. By inputting parameters like spring constant, displacement, and material properties, you can predict the spring’s performance and validate its suitability for your application.

Example: An automotive manufacturer might use the Online Spring Force Tester to simulate the performance of a new suspension spring design, ensuring it can handle the required loads and stresses before physical testing.

Step 5: Evaluate Cost and Lead Time

Cost and lead time are important factors in selecting the right replacement spring. Consider the following:

-

Cost Efficiency: Compare quotes from different manufacturers to ensure you are getting a competitive price for high-quality springs.

-

Lead Time: Assess the delivery times provided by manufacturers. Opt for manufacturers who can deliver within your project timeline without compromising on quality.

Recommendation: Acxess Spring offers competitive pricing and reliable lead times, ensuring you receive your springs promptly without sacrificing quality.

Ensure Peak Performance with Acxess Spring's Custom Springs

Finding the right replacement spring is crucial for maintaining the performance and reliability of your mechanical systems. By understanding your specific needs, using advanced tools for precise selection, and choosing reputable manufacturers, you can ensure that your springs meet all performance criteria. Tools like the Instant Spring Quote and the Online Spring Force Tester from Acxess Spring can simplify this process, providing you with high-quality, custom solutions tailored to your needs.

Don't let worn-out springs compromise your projects. Visit Instant Spring Quote today to get an instant quote for your custom springs and ensure your systems continue to run smoothly and efficiently. Take the first step towards optimal performance and reliability—trust Acxess Spring for all your spring replacement needs.